+86 10 8760 3028 ,+86 13581790576

MON–SAT:08:00–18:00

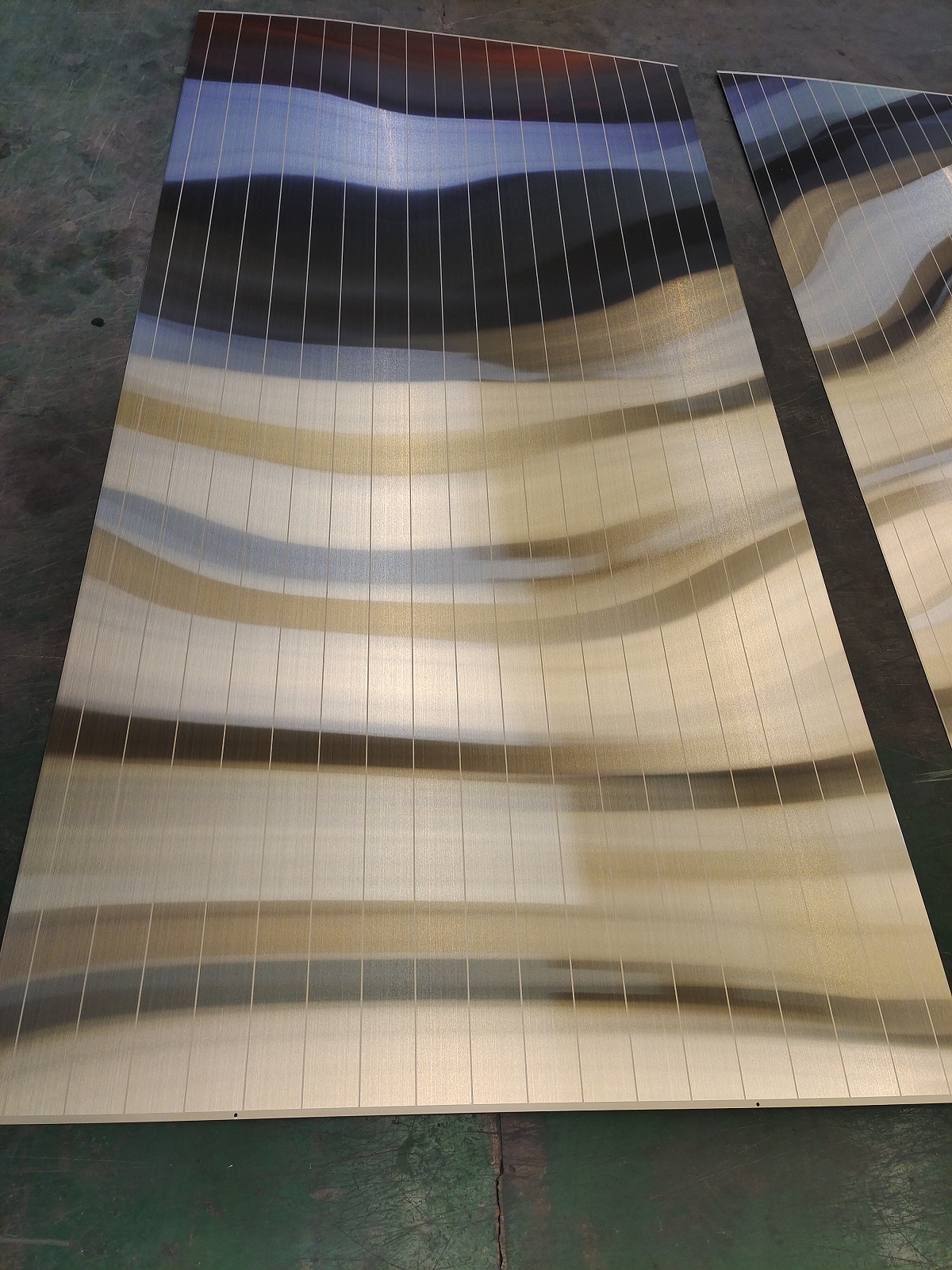

PVD Coating

Titanium plating: high hardness, wear resistance, high resistance, anti-adhesion, strong corrosion resistance coating properties: hardening, value-added, longevity, environmental protection, recycling Main features: the film has wear resistance, corrosion resistance, high hardness, dry lubrication, beautiful, gorgeous and so on.

Excellent adhesion - can be bent over 90 degrees without cracking or peeling (PVD coatings have high adhesion and durability). Other technologies, including electroplating and spraying, are not comparable. Anti-oxidation, anti-corrosion. In the normal environment, indoors or outdoors, are resistant to oxidation, do not fade, do not lose luster and do not leave traces. · It will not be damaged under normal use. Does not fade easily. Easy to remove paint and handwriting.

Titanium plating is a kind of vacuum ion coating, is a widely used industrial superhard film technology, with its high hardness, low wear rate, low friction coefficient, strong corrosion resistance, adhesion resistance and other superior performance, widely used in the mold industry. Various molds and hardware products after titanium plating processing, can improve the surface hardness, increase wear resistance, greatly improve the surface wear resistance, corrosion resistance and so on. Therefore, titanium plating on the tool can increase the surface hardness and wear resistance of the tool to improve the service life.

Visit Us:

Call Us:

Copyright © Beijing Shenghe Zhongtai Stainless Steel Co., Ltd. All Rights Reserved | Sitemap